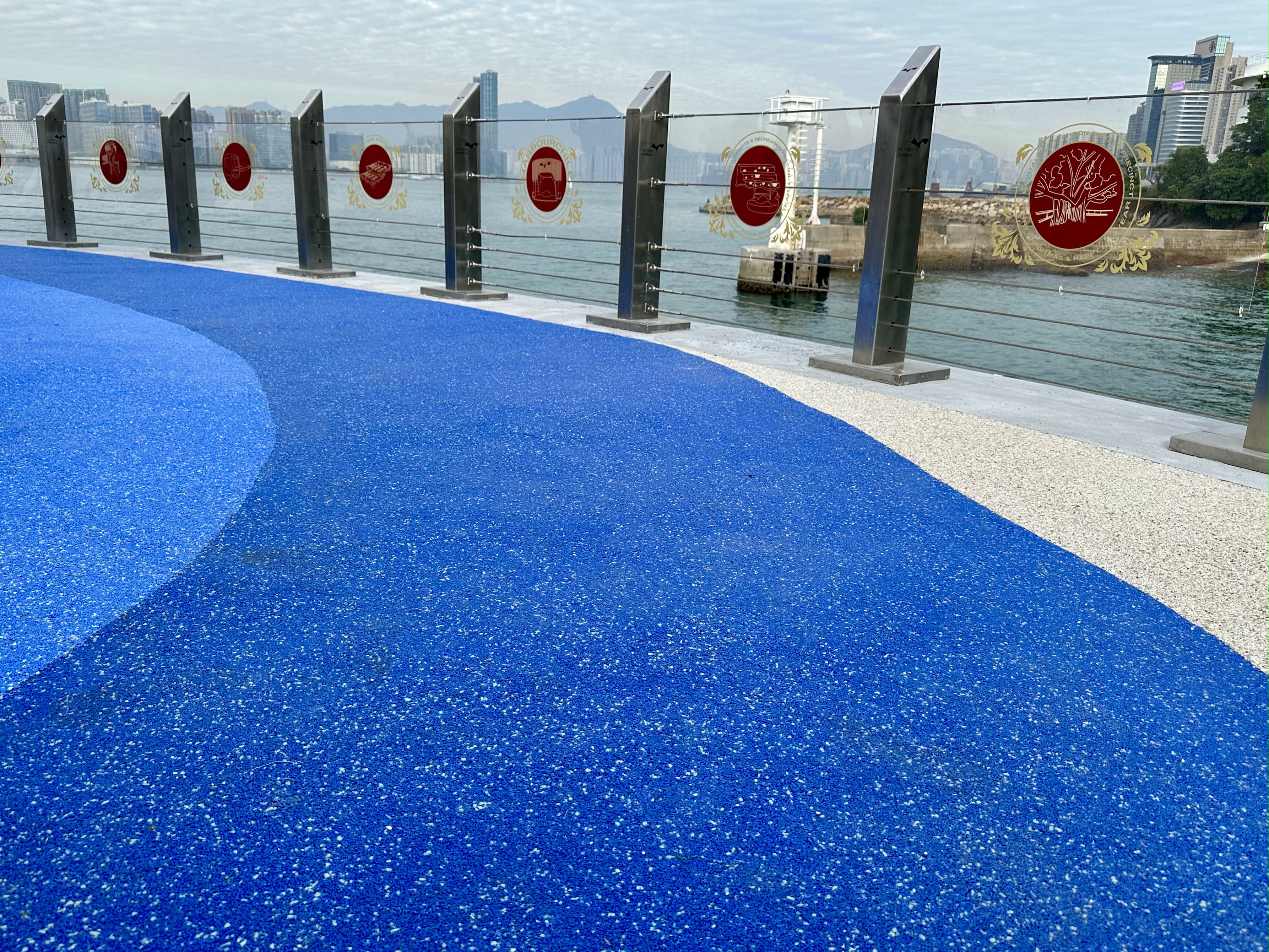

Strength and stability

Satisfactory resistance to the loads

associated heavy pedestrian traffic

Rainwater drainage

The system has sufficient rainwater drainage properties to eliminate surface